Gear shaving is a precision process in which the surface of a gear is finished by removing a thin layer of material using a shaving cutter. This process produces high-quality gears with precise tolerances and surface finishes. Gear shaving cutters are essential for this process, and choosing the right manufacturer is critical to achieving the desired results. This article will provide a comprehensive guide to selecting the right gear-shaving cutter manufacturer for your needs.

Understanding Gear Shaving Cutters

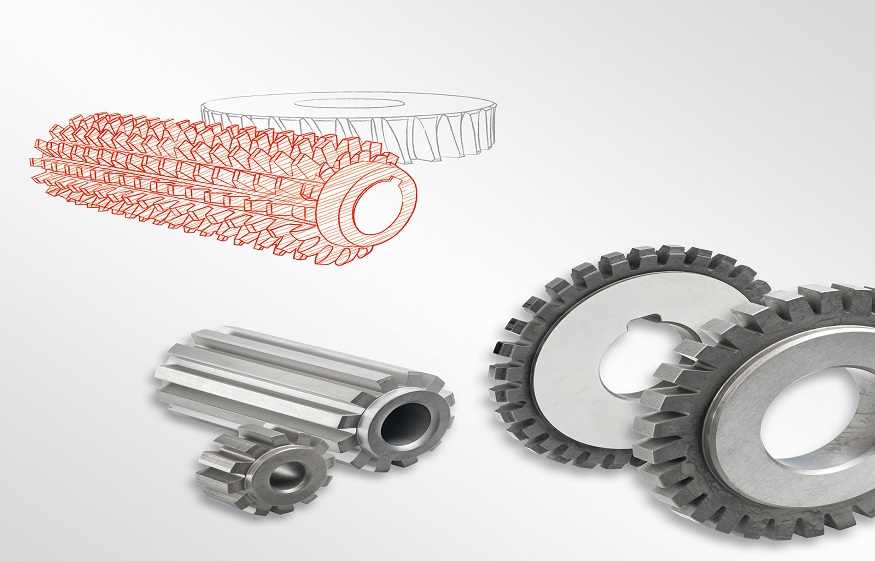

Before we dive into the selection process, it is essential to understand the different types of gear shaving cutters available. There are three main types:

Single-Axis Gear Shaving Cutters

Single-axis gear-shaving cutters are used to shave the teeth of cylindrical gears. They have a single cutting edge and are suitable for producing gears with a module of up to 10 mm.

Multi-Axis Gear Shaving Cutters

Multi-axis gear shaving cutters have multiple cutting edges and can produce gears with a module of up to 25 mm. They are suitable for producing both cylindrical and bevel gears.

Disc-Type Gear Shaving Cutters

Disc-type gear shaving cutters are used to shave bevel gears. They have multiple cutting edges and can produce gears with a module of up to 25 mm.

Factors to Consider When Choosing a Gear Shaving Cutter Manufacturer

When selecting a gear-shaving cutter manufacturer, several factors must be considered. These include:

- Quality

Quality is the most critical factor when choosing a gear-shaving cutter manufacturer. The manufacturer must have a proven track record of producing high-quality gear shaving cutters that meet your specifications. Look for manufacturers who use high-quality materials and advanced manufacturing processes to produce their cutters.

- Experience

Experience is also essential when choosing a gear-shaving cutter manufacturer. Look for manufacturers who have been in the industry for a long time and deeply understand the process. They should be able to provide expert advice and guidance on selecting and using gear shaving cutters.

- Customization

Every gear-shaving application is unique, and choosing a manufacturer who can provide customized cutters to meet your specific needs is essential. Look for manufacturers who offer a wide range of customization options, including cutter diameter, tooth form, and surface finish.

- Price

Price is always a factor when selecting a gear-shaving cutter manufacturer. Cheaper cutters may provide a different quality or performance than expensive ones. Look for manufacturers who offer a good balance of quality and price.

- Support

Finally, choosing a gear-shaving cutter manufacturer with excellent customer support is essential. They should be able to provide technical support, training, and maintenance services to ensure that your gear-shaving process runs smoothly.

Conclusion

Choosing the right gear-shaving cutter manufacturer is critical to achieving the desired results. Quality, experience, customization, price, and support are all crucial factors when selecting a manufacturer.

Remember to choose a manufacturer that can provide customized solutions that meet your specific needs, and consider the level of customer support they offer. With a suitable gear-shaving cutter and manufacturer, you can produce high-quality gears with precise tolerances and surface finishes, ensuring the success of your gear-shaving process.